Timber Frame

Scotts approaches timber frame with the same focus on product and service quality as it does with all its timber engineered products.

Our timber frame kits are designed in-house by our highly qualified and experienced design team, enabling us to provide our clients with rational and cost-effective solutions which take planning regulations into account.

Our clients range from self-builds to independent contractors and architects through to national housebuilders and from residential, one-off builds, self-builds, education to healthcare.

Future Proofed Housebuilding

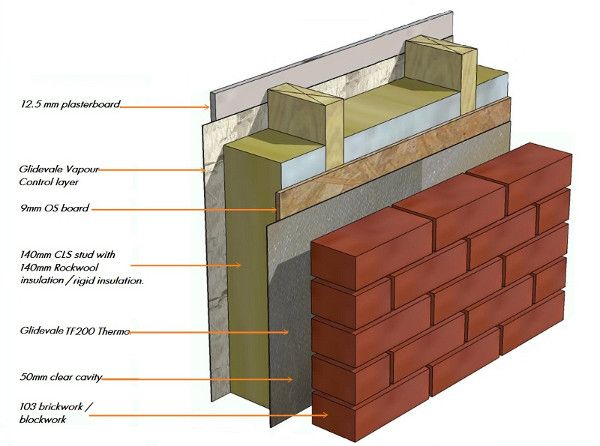

Catering for housing, apartments, flats commercial and educational developments, our Timber Frame division supports future proofing in readiness for Part L, as well as the drive to reduce the carbon footprint of construction projects, offering:

- Solutions ranging from 0.23 to 0.15 including semi-closed panels

- Windows and external cladding systems factory fitted if required.

- Increased scope for Pre-Manufactured Value (PMV) aligned to the Government’s MMC Definition Framework.

Our professional and experienced team work together to ensure your project is delivered on time, within budget and to the highest standards of quality and safety.

Dramatic Build Time Improvements

Using our systems, the erection of a timber frame kit starts when the foundation slab on the ground floor is complete, reducing initial time to build. Once erected, internal follow-on trades can gain access instantly, without having to wait for scaffolding to be removed. Overall, choosing timber frame can reduce build time by up to 30%

Carbon Footprint

Timber frame construction brings many benefits, not least of which are those which impact the carbon footprint of new developments. These include:

- Greater absorption and storage of carbon resulting in greener developments and supporting moves towards Net Zero carbon emissions.

- Up to 90% less waste produced on any timber frame site

Platform Construction

Scotts Timber Frame uses a platform construction method to erect timber frame. Each storey is framed with floor to ceiling height wall panels. Floor zones are constructed to create a platform from which the next storey can be constructed. Trusses can be craned into position separately or given enough site space, erected in banks at ground level and craned into position.

Teamwork

We can step into a project at any stage – assisting throughout; from estimating to initial engineering and design specifications to manufacturing and finally to cranage and installation on-site, providing the same first class, experienced service to your build.

Teamwork is particularly important – from joiners to crane operators – meaning we can schedule all builds accurately, and manage every aspect centrally, allowing us to be both flexible and reliable. This central coordination helps to reduce overall build costs.

ADDITIONAL SOLUTIONS

We also offer the following additional solutions for timber frame:

- Complete Supply and Fit packages for windproof and watertight homes; roofs ready for tiling and houses ready for first fixing.

- Our own fleet of delivery vehicles, and provision of cranage, improving site safety, flexibility on timings whilst reducing overall build times, costs and on-site storage

- Treatment to ensure the longevity of all exposed wood products in home building – all structural timbers we use are preserved in accordance with BS 5268 (part 5) code of practice for preservative treatment of structural timber.

- Quality Assurance – with all components of our timber frame buildings manufactured to a high quality and tolerance, in a controlled factory environment, all timbers are kiln dried and treated to protect them from insect attack and decay.

More and more developers, contractors and architects are realising the advantages and benefits of timber frame over traditional brick and block construction.

Talk to us today

For more information or to place an order, please contact us via phone on 01832 732366, email, or simply fill out your details and a member of our sales team will be in touch very soon to discuss your project requirements