The Ultimate Guide to Joists

Welcome to The Ultimate Guide to Joists, this guide is designed to be a resource for housebuilders of all sizes, offering practical information and guidance that provides invaluable insights into the use of joists.

With this guide, we aim to explain the complexities surrounding joists, and provide clarity on design considerations, material choices, and compliance with British Standards and Building Regulations.

Whether you are working on a large-scale development or a bespoke luxury project, our guide aims to support housebuilders at every stage, from planning and design to the delivery of the completed project.

Here are the discussion points in this guide:

~ Structural building components

~ Different types of joists

~ Considerations for housebuilders

~ Building standards and regulations

~ How to pick the right roof joist manufacturer

Structural building components

Roof joists and beams are key structural building components of a roof, they ensure the stability and safety of the roof.

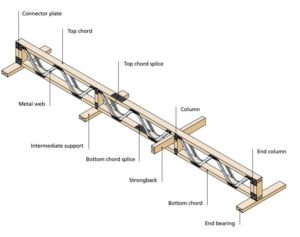

Joists (commonly known as metal web joists or open web joists) are laid horizontally, with parallel top and bottom chords typically joined with made from strength-graded timber and connected by engineered steel web.

The web features a series of strategically designed ‘zig-zags’. The components of a joist often include a connector plate, top chord, metal web, top chord splice, bottom chord splice, column, strong back, bottom chord, end column, and end bearing. Roof joists help to support the weight of your roof and can be used in both flat and pitched roof constructions, they can also be exposed or concealed.

(Image courtesy of Trussed Rafter Association)

This configuration provides strength and support for the roof structure while maintaining an open web design, allowing for seamless integration of building services such as electrical conduit, plumbing and HVAC systems, and minimising the need for modifying the joists.

Benefits of metal web joists

The zig-zag design isn’t the only advantage of metal web joists, some of the other benefits include:

~ Wide range of sizes: Depending on the needs of the project, metal web joists can vary and be adjusted accordingly at design, these include the depth, length, and specification.

~ Design flexibility: The clever design and ability to withstand heavy loads mean they can reduce the need for load-bearing intermediate walls and allow the designer to create something that is tailored to the project.

~ Lightweight design: The open web structure means they are lighter than solid timber joists.

~ Reduced costs: The flexibility in design and faster erection times can result in reduced building costs.

~ Made-to-measure design: As each project is made to measure, it can eliminate wastage.

Roof beams

Beams are typically thicker and act as a primary support to joists, they span across the building, as they are the primary load-bearing element in the roof, providing support to the roof or floor above and keeping them securely in place. At the same time, they can provide support for the rest of the roof, this includes joists, trusses, battens, or roofing materials.

Both joists and beams form the skeletal framework of the roof and act as the essential building components that ensure the ability to withstand various loads. Although both a roof joist and roof beam share common characteristics of being a structural roof element, there are several types of roof joists available.

Different types of joist

While serving the important function of supporting the roof, there are different types of roof joists available that housebuilders need to be aware of. From traditional solid timber joists to metal web joists, the choice will depend on factors such as span length, load requirements, and desired properties.

Engineered Wood Joists (I-Joists):

Engineered Wood Joists (EWJs) are also known as I-joist, they are created from materials such as Laminated Veneer Lumber (LVL) or I-joists, offering a balance of strength, stability, and sustainability. LVL, composed of bonded veneers, imparts superior strength, while I-joists, featuring an “I” shaped cross-section, optimise material usage.

EWJs are designed to deliver consistent performance, with the added benefit of being more resource-efficient, contributing to sustainable construction practices.

Metal Web Joists:

Metal web joists are often sold under brand names such as Posi-Joist™, easi-joist®, and Eco Joists. Metal web joists are also known as open web joists. These joists are often used over I-joists due to their span capabilities without the need for drilling.

The open-web design of Posi-Joists™ not only enhances their load-bearing capacity but also facilitates the seamless installation of service pipes, making them a go-to choice for modern constructions. The lightweight nature of the timber, coupled with the strength derived from metal webs, enables these joists to span greater distances than their traditional counterparts. This not only allows for flexible architectural designs but also provides a wider fixing point for plasterboard and chipboard, enhancing the overall efficiency of the roofing system.

When it comes to metal web technology for construction, both standard metal web joists and the easi-joist® system play pivotal roles. However, their characteristics set them apart, particularly in terms of design, versatility, and sustainability.

At Scotts Timber Engineering, we supply Posi-Joist™ are they are a form of metal web joist system that can be used for both floor and roof structures, they are designed and manufactured to suit different projects. The Posi-Joist™ system is licensed by MiTek Manufacturers in a factory-controlled conditions.

Joist considerations for housebuilders

Roof joists can offer several advantages in terms of flexibility, ease of installation, and durability. Installation of roof joists require qualified personnel with the knowledge and experience in handling and securing these components.

At the same time, the chosen joist must comply with relevant building codes and regulations, which is why we will recommend housebuilders to ask for certification, and choose to use a member of the Trussed Rafter Association.

Building standards and regulations

There are several standards and regulations housebuilders will need to be aware of, this is particularly important if your supplier is a member of the Trussed Rafter Association – they will be required to be aware and follow the standards:

British Standards (BS):

~ BS EN 1995-1-1:2004+A2:2014 (Eurocode 5) – Design of timber structures. General. Common rules and rules for buildings

~ NA to BS EN 1995-1-2:2004 – UK National Annex to Eurocode 5. Design of timber structures. General. Structural fire design.

~ PD6693-1:2019 – Recommendations for the design of timber structures to Eurocode 5: Design of timber structures. General. Common rules and rules for buildings.

~ BS EN 14250:2010 – Timber structures. Product requirements for prefabricated structural members assembled with punched metal plate fasteners – Harmonised European Product Standard

~ EN ISO 9001:2015 – Quality management systems. Requirements.

Building Regulations:

~ Approved Document A (Structure): focuses on the structural stability and safety of buildings in England. It applies to all new buildings, extensions, and alterations, ensuring they can withstand various loads while remaining safe for its occupants.

~ Approved Document L (Conservation of Fuel and Power): focuses on the energy efficiency of buildings in England. It applies to new buildings, extensions, and alterations. Part L aims to reduce energy consumption in buildings; minimise CO2 emissions from buildings; and improve the overall sustainability of the built environment. Part L is divided into two volumes; volume 1 focuses on dwellings which cover the specific requirements for residential buildings; volume 2 focuses on buildings other than dwellings (such as schools and offices).

How to pick the right roof joist manufacturer

Roof joists are a key structural building component, housebuilders need to identify the project requirements, such as the type of roof joist you are looking for, span length, load capacity, and any unique design considerations. Your supplier should be a reputable company that is experienced in designing the right joist for your project and also can provide installation support and guidance.

At Scotts, we always recommend that housebuilders choose a member of the Trussed Rafter Association (TRA) which is the leading authority on trussed rafter and metal web joists in the UK and Ireland.

Scotts Timber Engineering – your partner for roof joists

At Scotts Timber Engineering, we take pride in our experience and commitment to deliver high-quality truss manufacturing solutions. Our extensive work with major volume housebuilders, specialist luxury homebuilders and other developers across the country.

Read our: top three learnings from working with housebuilders for more than 25 years.

We are part of the prestigious Scotts of Thrapston Group which was established over 100 years ago. The company has a strong reputation for high-quality, PEFC-certified specialist timber products and, as a long-standing member of the Trussed Rafter Association, Scotts maintains high technical and quality assurance standards and a commitment to best practices and the TRA’s code of conduct.

Contact our team of experts who can offer guidance to ensure a seamless and stress-free experience for your project.

Click the link below to fill out our contact form, or call us on 01832 732366.

You might also like to read our: Ultimate Guide to Roof Trusses

If you would like to speak to one of our team, simply fill out your details below and a member of our sales team will be in touch very soon to discuss your project requirements.

If you would like to speak to one of our team, simply fill out your details below and a member of our sales team will be in touch very soon to discuss your project requirements.

- Copyright © Scotts of Timber 2024

- Privacy Policy